Antireflection Design of DFB Laser

- Tracy

- Apr 5, 2023

- 3 min read

Updated: Oct 23, 2025

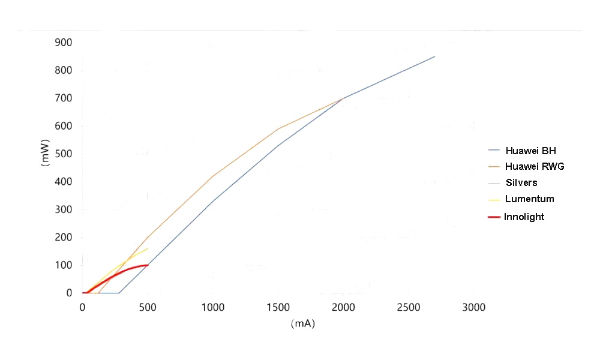

InnoLight has launched a high-power anti-reflection laser. InnoLight's CW high-power laser chip can reach 100mW optical power. We put InnoLight’s lasers and other peers’ lasers into the same coordinate system for comparison as shown in the figure below.

The PI curve given by InnoLight is the data at 25°C. According to this data, the electro-optical efficiency of the linear segment is about 29%, the efficiency of the two Lumentum designs at room temperature is about 40%, and the efficiency of the Silvers is about 27%.

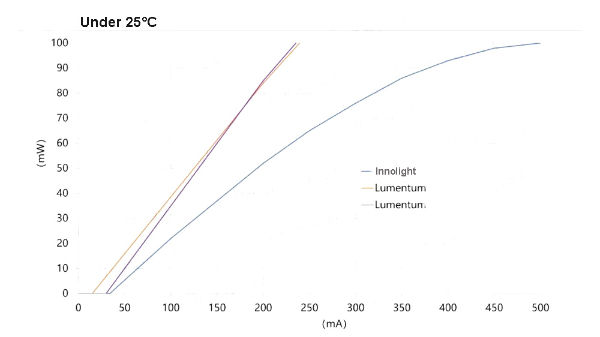

First, incorporate the data of Lumentum into the horizontal and vertical axes given by InnoLight. Then fill in the data of InnoLight into the coordinate axis of Lumentum. Then let's review the 100mW DFP again.

Lumentum's 100mW laser actually refers to a current of 500mA at room temperature, and a laser power of 200mW, so that it can still maintain an output optical power of 100mW after the efficiency drops at high temperatures (without TEC cost).

InnoLight provides a current of 500mA. When the temperature is 25°C, the optical output power can reach 100mW, and it is in the saturation region. To keep this power from dropping, it is necessary to increase TEC for cooling. However, the cost reduction measure proposed by InnoLight is to cancel the isolator. Without the isolator, it can resist the reflection of -19.8dB.

In the standard protocols of many optical modules, you will see these parameter requirements, RIN, and return loss tolerance, which is also called reflection tolerance. Return loss tolerance and reflection tolerance, they actually express the same meaning, taking log, just the reflection tolerance is -17.1dB, the meaning of these parameters is very clear, the return loss of 17.1dB is 2 % reflection.

Controlling the reflectivity to 2% puts a lot of pressure on the various joints of the optical fiber.

The plugging and unplugging of optical fibers, whether it is LC connectors or MPO connectors, right? The core of the single-mode conventional optical fiber is about 9 μm, some are 4 μm, and some are 10-13 μm, each of which has different uses.

The purpose of the connector is to effectively contact the optical fiber

However, a single dust can ruin everything. The particle size of dust recognizable by the naked eye is about 100 μm. In order to control the cleanliness of the atmosphere, we need to test PM2.5 and PM10, which refers to the 2.5 μm invisible to the naked eye. Granular dust, dust with a particle size of 10μm, there are countless in the air.

A small dust falls on the optical fiber, then the incoming optical fiber head cannot be effectively and directly contacted, and a stone in the shoe is stuck. The light of the optical fiber will go through a short period of time from glass to air, from the refractive index of glass optical fiber of 1.5 to the refractive index of air of 1.0, and the reflectivity of this interface is 4.2%. Therefore, in order to reduce the pressure on the laser, the fiber group needs to design the total reflectivity of the entire link to be less than 2%.

Let's take a look at the anti-reflection design of other manufacturers

In anti-emission, the easiest to implement is to use an isolator. Ordinary DFB is a common single-mode laser design. The cross-sectional structure is commonly seen as follows. Today, different colors are used to distinguish the two types of materials, InP and InGaAsP. Quantum wells can be made of InGaAsP or AlGaInAs. Make a gesture.

The anti-reflection tolerance of conventional DFB is about -25dB, and -25dB is the reflectivity of 3/1000. The chip cannot withstand the reflection of 0.3%, not to mention that they are required to resist the reflection of 2%, or even 6%, 10% reflections are unlikely. too difficult.

If a 15dB isolator is added, it can resist 2% reflection. If the reflection of the system is larger, a higher isolation design can also be selected.

The current CW DFB basically has an oblique light output design to improve the anti-reflection capability. This waveguide structure is a conventional design.

There are also some manufacturers whose design starts from the cross section.

XINXIN GEM Technology provides high-quality ceramic submount - DPC (Direct Plating Copper) for high power lasers. Our DPC performance leads to very high efficient output power.

Test report of GEM's DPC submount as follow:

Comments